Down to ±0.05mm Machining Precision Achieved in Our Sheet Metal Machinery

Since 2003, T&L Sheet Metal Solution has been a leading China high-end CNC sheet metal equipment manufacturer, offering a range of customized bending machines and cnc punching solutions to deliver massive efficiency and cost savings for you.

Play Video

Trusted leading CNC sheet

metal fabrication equipment Supplier

T&L is your trusted partner in CNC sheet metal machinery, committed to delivering top-quality press brakes, laser cutting machines, and panel benders. For inquiries or customization requests, feel free to contact us anytime.

1-Hour Quick Response

Our team responds to inquiries within 1 hour to address issues promptly.

12-Hour Solution Delivery

We aim to deliver effective solutions within 12 hours to minimize downtime.

On-Site Technical Support

We provide video and remote support for efficient installation and setup.

Online Installation Guidance

For complex setups, our specialists provide on-site installation to ensure smooth operation.

Global Localized Service

Local distributors in the UAE, Saudi Arabia, and Russia provide faster regional support.

2-Year Warranty

We provide a comprehensive 2-year warranty and we cover both the cost of replacement parts and all associated shipping expenses.

Simple Contact Form

One-Stop CNC Sheet Metal Working Solutions

Leading in sheet metal cutting and bending, we offer a diverse range of products, each engineered to boost your metal processing capabilities.

Panel Bender

Panel Bender

• 300%+ efficiency boost

• ±0.005mm repeat accuracy

• Automated design, minimal manual input

• All-electric servo, energy-efficient

• ±0.005mm repeat accuracy

• Automated design, minimal manual input

• All-electric servo, energy-efficient

Press Brake

Press Brake

• Up to 2000+ tons high-strength bending

• 30%+ energy savings with servo drive

• Multi-axis for complex workpieces

• Automatic robot bending options available

• 30%+ energy savings with servo drive

• Multi-axis for complex workpieces

• Automatic robot bending options available

Punching Machine

Punching Machine

• Hard-oxidized crankshaft, high wear resistance

• High-precision die adjustment to 0.1mm

• User-friendly CNC system

• Quick die change, minimizing downtime

• High-precision die adjustment to 0.1mm

• User-friendly CNC system

• Quick die change, minimizing downtime

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine

• Auto-focus laser, rapid piercing

• High optical conversion efficiency

• Anti-vibration hollow frame

• Zoned dust removal, smoke-free cutting

• High optical conversion efficiency

• Anti-vibration hollow frame

• Zoned dust removal, smoke-free cutting

V Grooving Machine

V Grooving Machine

• High-temperature tempering, lasting precision

• Rack and pinion drive, smooth cutting

• Servo-driven, precise positioning

• Flexible tool holder options

• Rack and pinion drive, smooth cutting

• Servo-driven, precise positioning

• Flexible tool holder options

Shearing Machine

Shearing Machine

• Welded steel, strong rigidity

• Adjustable shearing angle, reduced deformation

• Imported screw and guide rail, precise positioning

• CNC system, automatic back gauge positioning

• Adjustable shearing angle, reduced deformation

• Imported screw and guide rail, precise positioning

• CNC system, automatic back gauge positioning

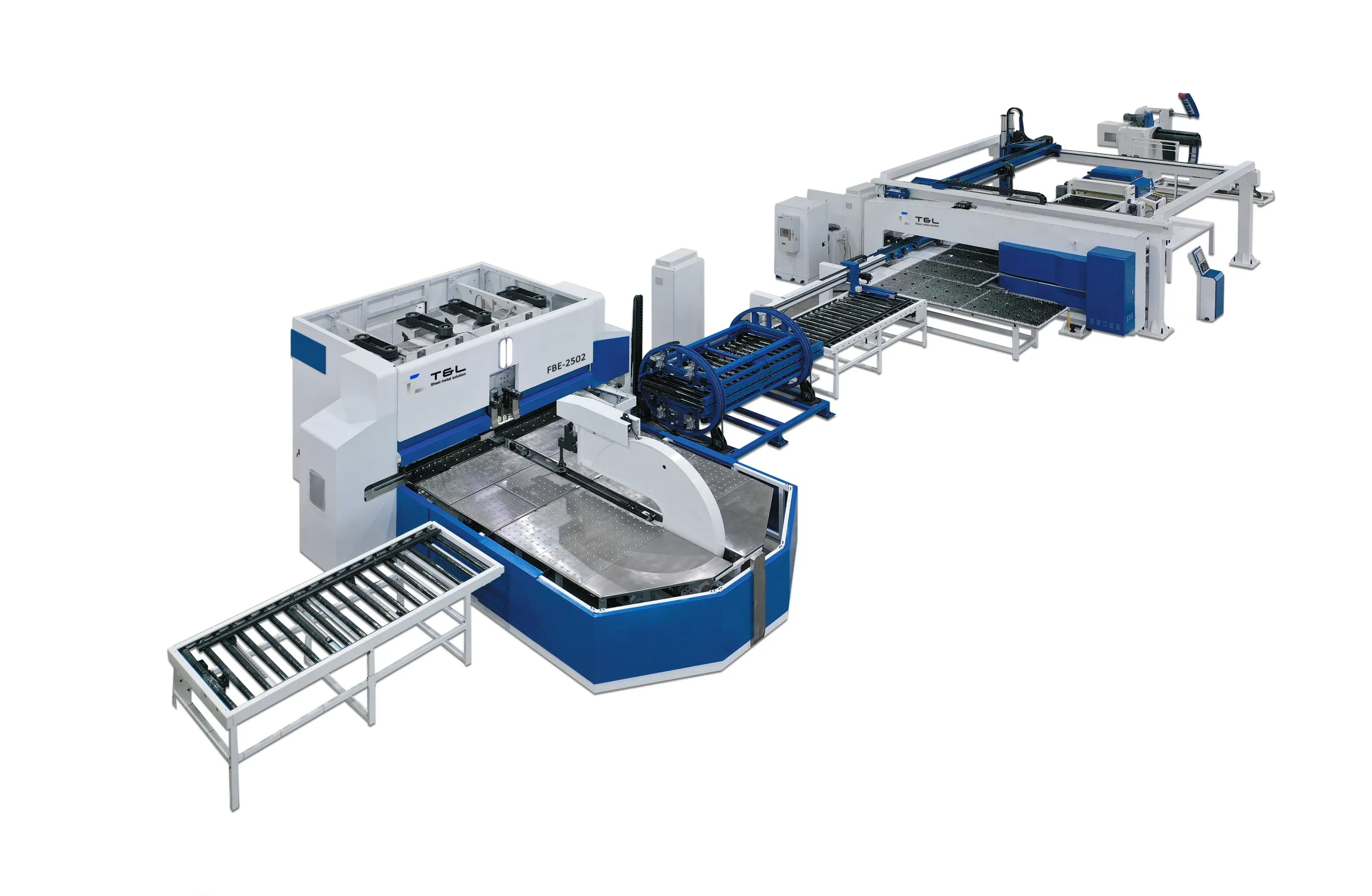

Automatic Production Line

Automatic Production Line

• 100% automation

• Customizable solutions

• Multi-functional system

• Customizable solutions

• Multi-functional system

Built for Any Sheet Metal Industry Needs

Our advanced CNC technology and customization expertise enable us to provide precise sheet metal solutions tailored to the specific needs of every industry.

Metal Job Shop

Ensure precision and consistency in cutting, bending, stamping, and welding materials like steel, stainless steel, aluminum, and copper. Flexibly manage small-batch customization and large-scale production.

Elevators

Achieve consistency in manufacturing carriages, doors, control cabinets, and guide rails through high-precision processing. Optimize space and reduce safety risks to efficiently manage complex demands.

Electric Cabinets

Quickly manufacture every component of an electric cabinet, from enclosure cutting to internal brackets, precisely to your specifications, achieving efficient production and a perfect fit.

Metal Gates

Efficiently produce all door components, from standard to intricate designs, ensuring structural strength and visual appeal, while meeting diverse requirements and optimizing material use to reduce costs.

Furniture

Flexibly produce a variety of furniture and components, from standard to custom designs, ensuring maximum efficiency and rapid delivery by utilizing precise machining and automation for optimal material use.

Automotive

Support high-volume production with advanced bending, cutting, and punching solutions. Maximize efficiency and precision for body panels, powertrains, and structural parts to meet automotive safety standards.

Aerospace

Achieve aerospace-level precision in lightweight components like fuselages and wings using multi-axis bending, drilling, and laser cutting, ensuring compliance with safety, durability, and weight requirements.

Machinery Manufacturing

Providing multi-process solutions for machine frames and enclosures, addressing customization, strength, and material efficiency in industrial machinery production.

Curtain Wall

Accurately produce curtain wall frames and panels to ensure durability, structural integrity, and aesthetic appeal. Optimize production efficiency while allowing for high customization in architectural designs.

Road Construction

Produce road components like guardrails and signage with advanced shearing, forming, and punching. Ensure efficient production, safety compliance, and durability for large projects.

Steel Structure

Offer cutting, drilling, and forming solutions for steel beams and columns. Enhance production for projects needing strength, precision, and quick assembly.

New Energy Industry

Ensure precise CNC processing for energy storage systems, battery enclosures, and energy equipment, achieving high output, durability, and material efficiency in renewable energy solutions.

Metal Job Shop

Ensure precision and consistency in cutting, bending, stamping, and welding materials like steel, stainless steel, aluminum, and copper. Flexibly manage small-batch customization and large-scale production.

View More

Elevators

Achieve consistency in manufacturing carriages, doors, control cabinets, and guide rails through high-precision processing. Optimize space and reduce safety risks to efficiently manage complex demands.

View More

Electric Cabinets

Quickly manufacture every component of an electric cabinet, from enclosure cutting to internal brackets, precisely to your specifications, achieving efficient production and a perfect fit.

View More

Metal Gates

Efficiently produce all door components, from standard to intricate designs, ensuring structural strength and visual appeal, while meeting diverse requirements and optimizing material use to reduce costs.

View More

Furniture

Flexibly produce a variety of furniture and components, from standard to custom designs, ensuring maximum efficiency and rapid delivery by utilizing precise machining and automation for optimal material use.

View More

Automotive

Support high-volume production with advanced bending, cutting, and punching solutions. Maximize efficiency and precision for body panels, powertrains, and structural parts to meet automotive safety standards.

View More

Aerospace

Achieve aerospace-level precision in lightweight components like fuselages and wings using multi-axis bending, drilling, and laser cutting, ensuring compliance with safety, durability, and weight requirements.

View More

Machinery Manufacturing

Providing multi-process solutions for machine frames and enclosures, addressing customization, strength, and material efficiency in industrial machinery production.

View More

Curtain Wall

Accurately produce curtain wall frames and panels to ensure durability, structural integrity, and aesthetic appeal. Optimize production efficiency while allowing for high customization in architectural designs.

View More

Road Construction

Produce road components like guardrails and signage with advanced shearing, forming, and punching. Ensure efficient production, safety compliance, and durability for large projects.

View More

Steel Structure

Offer cutting, drilling, and forming solutions for steel beams and columns. Enhance production for projects needing strength, precision, and quick assembly.

View More

New Energy Industry

Ensure precise CNC processing for energy storage systems, battery enclosures, and energy equipment, achieving high output, durability, and material efficiency in renewable energy solutions.

View More

99.9% Metalworking Needs

Covered with Our Custom Solutions

Our R&D team of 30+ experts, with over 10 years of experience,

excels at precisely designing and tailoring sheet metal processing equipment to meet your exact specifications.

Processing Capacity

Machining Function

Processing Capacity

Processing Capacity

- Maximum Machining Size

- Machining Speed

- Machining Precision

- Maximum Bending or Punching Pressure

- Equipment Stroke

- Throat Depth

- Material Handling Range

- Number of CNC Axes

- Die Opening Height

- More

Machining Function

Machining Function

- Grooving Function

- Shearing Function

- Servo Motor Configuration

- Laser Safety Protection Function

- Real-time Bending Angle Detection Function

- Short Knife Auxiliary Bending Function

- Sheet Support and Positioning Device

- Quick Die Change System

- Intelligent Loading and Unloading System

- More

01

Requirements Analysis

Detailed consultation to understand your production needs, technical requirements, and specific industry standards.

02

Technical Design

Our engineering team develops customized specifications and solutions based on your requirements, including detailed technical drawings.

03

Solution Review

Collaborative review of the proposed solution, ensuring all specifications meet your needs before production begins.

04

Manufacturing & Testing

Production of your custom equipment with comprehensive quality control and 72-hour trial operation testing.

05

Delivery & Support

Professional delivery, installation guidance, and comprehensive training to ensure optimal equipment performance.

What Makes Us Trusted

by Thousands of Customers

Cutting-Edge Automation Technology

Machining Precision Down to ±0.05mm

Flexible Customization Capabilities

Innovative R&D for Next-Level Solutions

Exceptional Value for Money

100% Quality Control

7-30 Days Fast Delivery

Robust After-Sales Service

Manufacturing Precision Sheet Metal Equipment Since 2003

T&L specializes in precision processing equipment manufacturing, offering exceptional machining and R&D capabilities. Our state-of-the-art equipment delivers high-precision processing for large-tonnage and wide-width materials, surpassing industry standards by 30%. With streamlined production processes, we guarantee fast delivery within 7-30 days.

Years Experience

0

+

Plant Area

0

㎡

Annual Capacity

0

+

Valid Patents

0

+

50+ Tests for Reliable Delivery of Every Unit

Our skilled QC team enforces a comprehensive quality management system to ensure our equipment is free from defects and meets your market standards.

Strictly check raw materials and components per inspection reports and standards.

1

Conduct in-process inspections based on drawings and key quality control points.

2

Test geometric precision, positioning, hydraulic components, electrical systems per national standards.

3

Conduct a 72-hour trial operation before delivery.

4

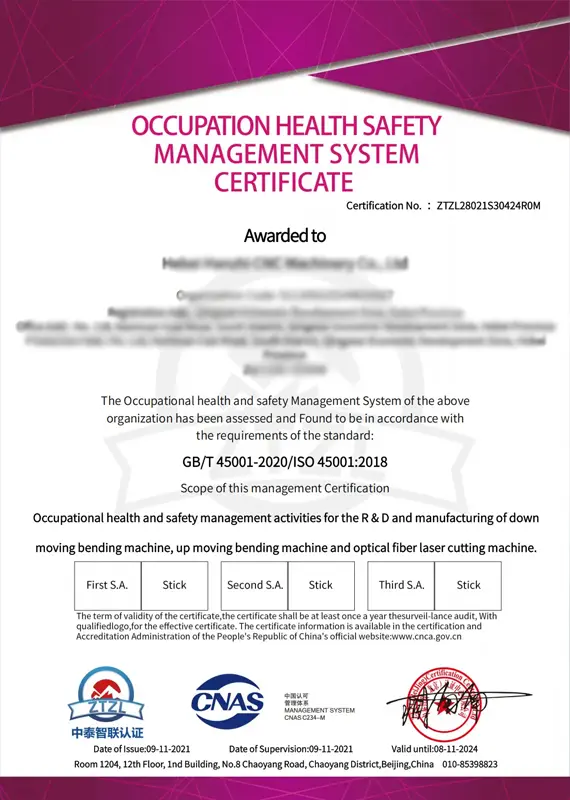

T&L's Commitment to Quality

Our products and facilities are certified by leading authorities, ensuring top quality, safety, and compliance standards.

More Than Just Sheet Metal Machinery,Your Partner in Business Growth

Copyright © 2025 Shanghai T&L Sheet Metal Solution All Rights Reserved.