Model | Unit | PE-3513 | PE-6020 | PE-8025 |

Bending Force | KN | 30 | 40 | 50 |

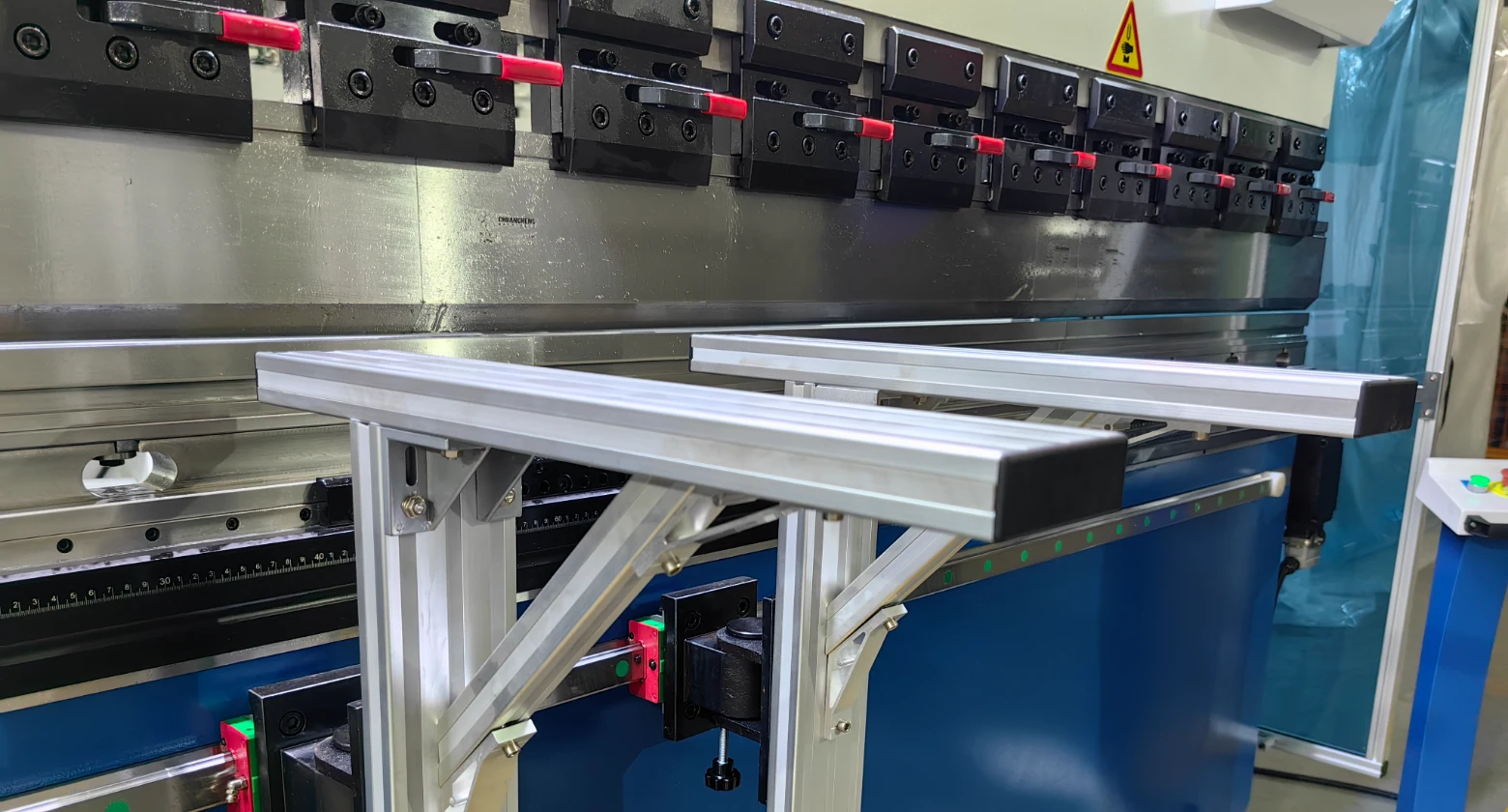

Bending Length | mm | 1360 | 2000 | 2500 |

Distance Between Uprights | mm | 1240 | 1900 | 2380 |

Throat Depth | mm | 270 | 350 | 400 |

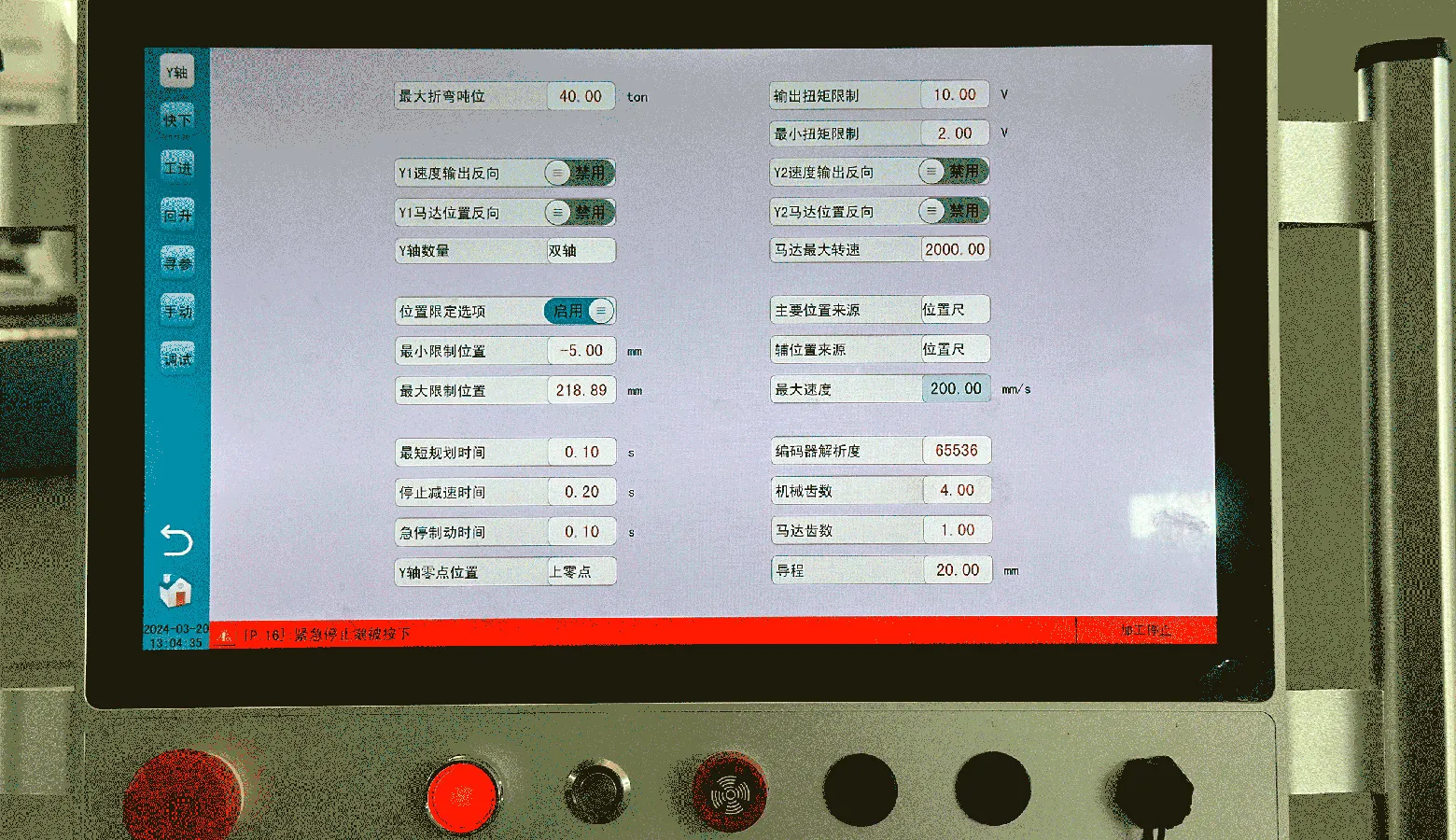

Ram Stroke | mm | 180 | 180 | 180 |

Opening Height | mm | 460 | 460 | 460 |

Ram max. speed | ||||

Approaching | mm/s | 200 | 200 | 180 |

Working | mm/s | 5-30 | 5-30 | 5-30 |

Returning | mm/s | 200 | 200 | 180 |

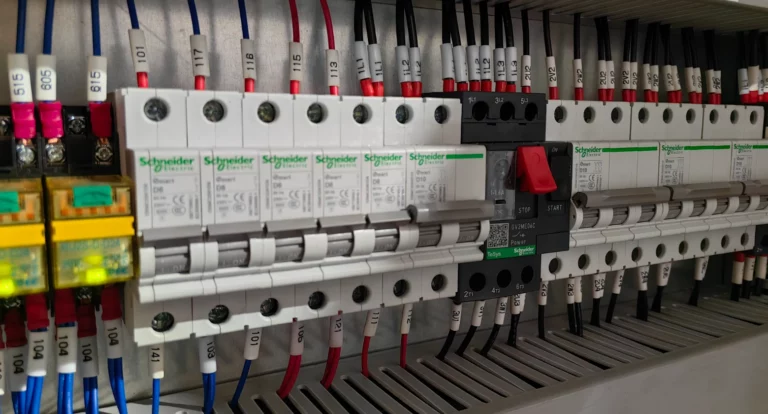

Main Power | KW | 11 | 16 | 21 |

Dimension | mm | 1800 x 1700 x 2500 | 2500 x 1800 x 2550 | 3100 x 1900 x 2600 |

Weight | kg | 5500 | 7000 | 8500 |

Copyright © 2025 Shanghai T&L Sheet Metal Solution All Rights Reserved.