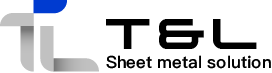

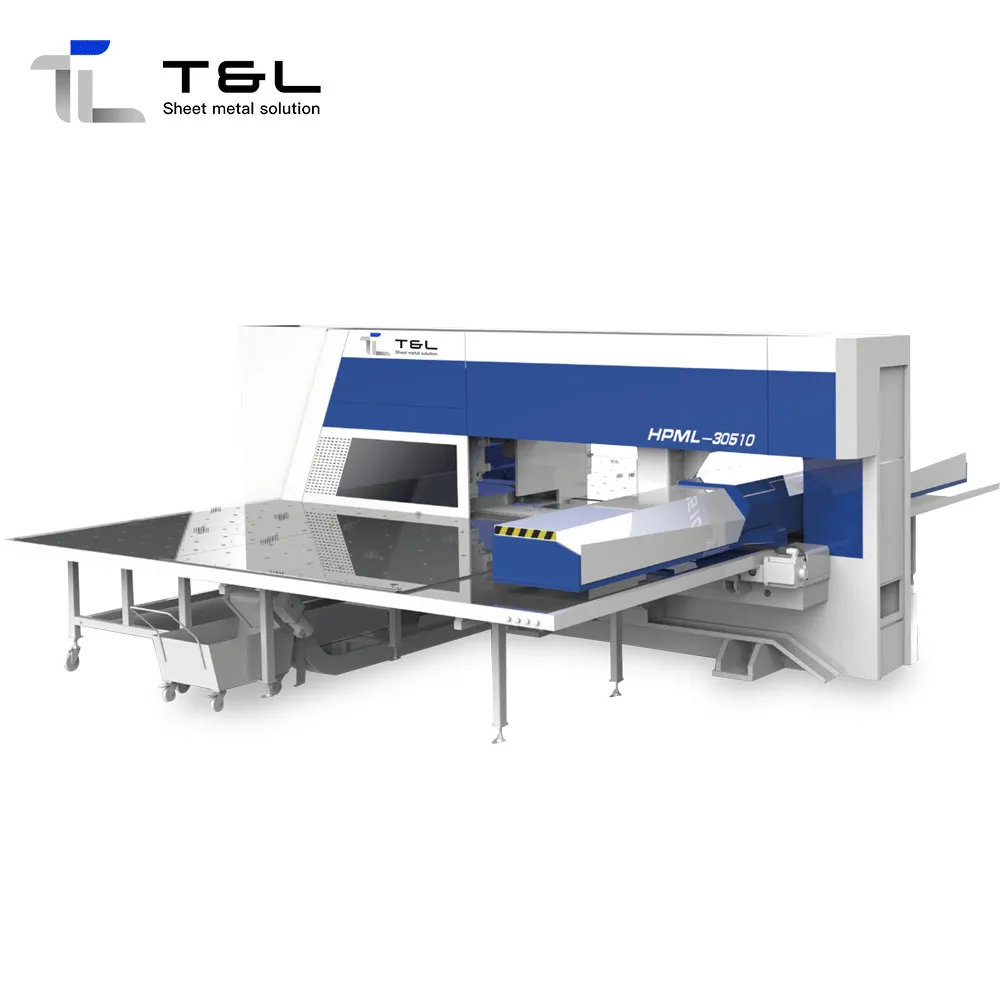

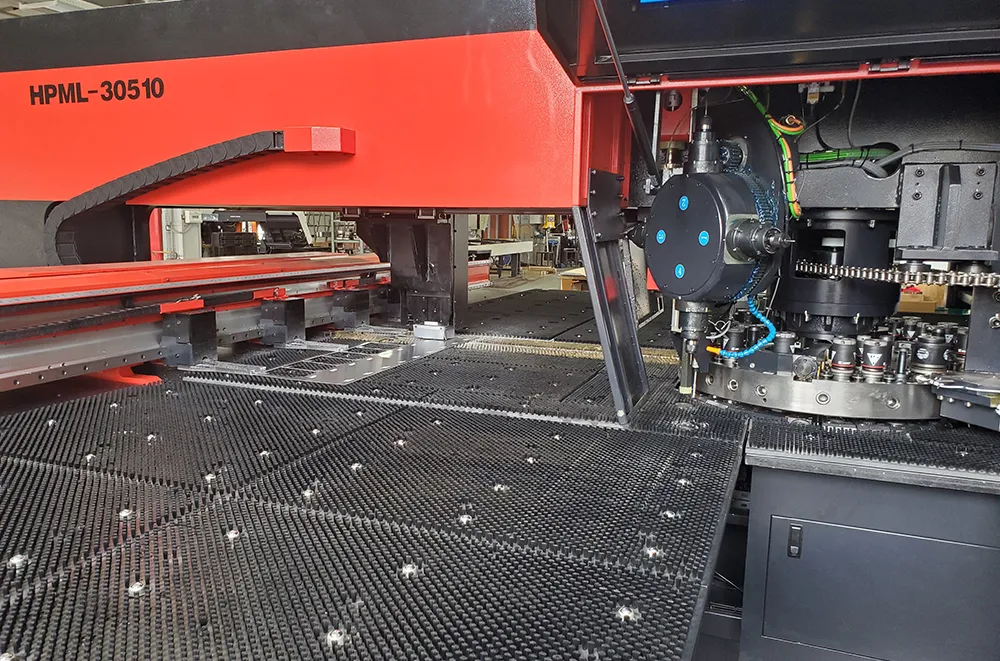

HPML-30510 Turret punch & Laser cutting Combination Machine

Model: MTE-300

Brand Name: T&L

Highlights:

- Equipped with laser cutting to realize fully flexible processing

- 38 Work stations, more tooling choices

- Automatic tapping device

- High effiency and high stability, multi-function

Applications:

- Electric cabinet

- High Precision Parts

- Elevator

Technical Parameter

| Model | Unit | HPML-30510 |

|---|---|---|

| CNC System | Siemens | |

| Laser cutting power | kw | 3 |

| Max. Punch Force | ton | 30 |

| X axis stroke | mm | 2500 |

| Y axis stroke | mm | 1500 |

| One time positioning processing plate size | mm | 2500*1500 |

| Max. thickness | mm | 3.0/6.35 |

| Max. Sheet weight | kg | 180 |

| Punch/Cut separate processing accuracy | mm | ±0.1 |

| Punch & Cut combine processing accuracy | mm | ±0.15 |

| Ram stroke | hpm | 2000 |

| Punching frequency (1mm step, 6mm punching stroke) | hpm | 700 |

| Punching frequency (25.4mm step, 6mm punching stroke) | hpm | 400 |

| Max. Punch Diameter per Time | mm | 88.9 |

| No. of Station | 38 | |

| AI | 2 | |

| Axis | 11 | |

| Overall size | mm | 8000*8000*2300 |

| Gas consumption | CL/Min | 250 |

| Warranty | Years | 2 |

Specifications apply to standard models. T&L reserves the right to adjust data without notice.

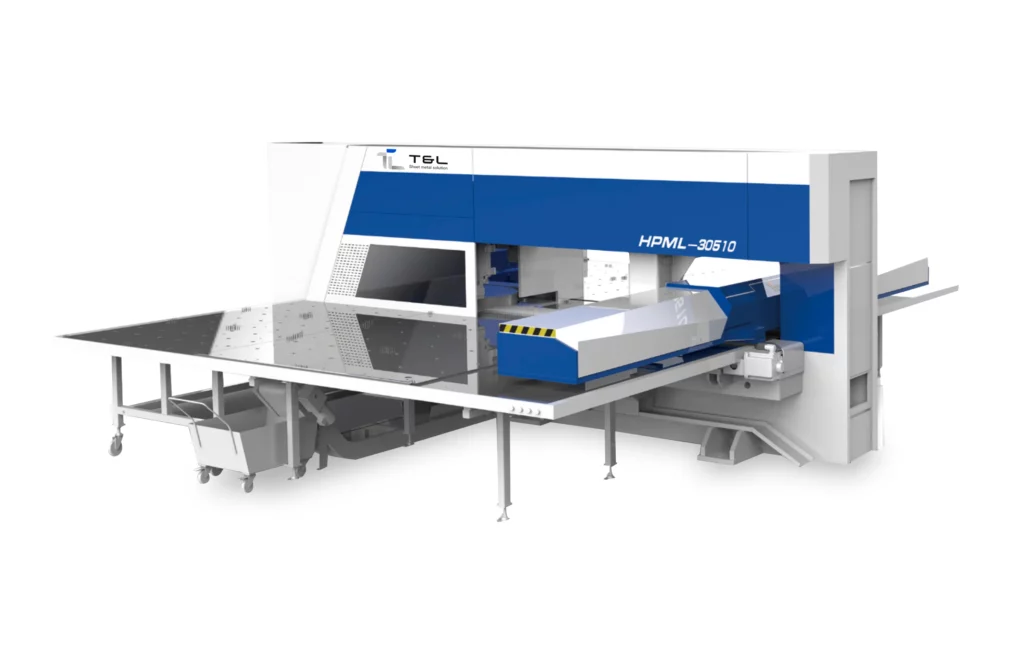

Machine Configuration Overview

Machine Frame

O-shaped closed steel plate is used to weld the

fuselage, and the residual stress is completely

removed after stress relief annealing.

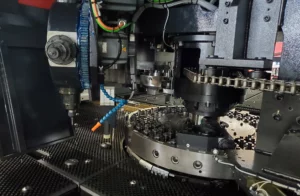

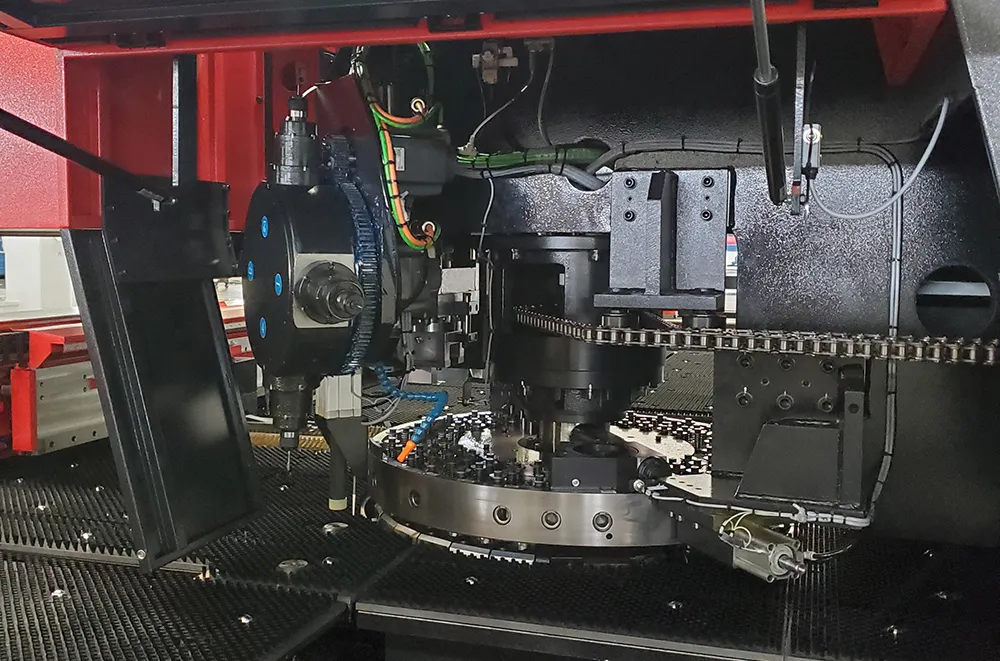

Turret

The thick turret structure is made of high-strength alloy steel and precision-machined. It has strong oxidation resistance and bearing capacity, and excellent vibration absorption and precision guiding performance.

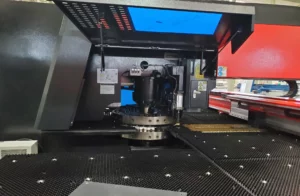

Laser Cutting Device

Optical fiber loop and fiber head detection, water leakage sensor and complete safety measures, multiple protection for laser and personnel.

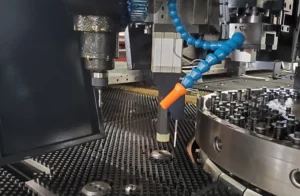

Floating pneumatic clamp

Increased the number of options for the punch tapping device. Through the combination of integrated tapping technology and stamping process.

Machine Configuration Overview

Trust T&L: Leading China Sheet Metal Machine Manufacturer

Reliable Imported Components

Advanced Manufacturing Capabilities

Broad Product Line Coverage

Comprehensive Customization Capabilities

Efficient Multi-step Quality Inspections

High-Value Pricing with Superior Quality

7-30 days Rapid Delivery

1-Hour Response & 12-Hour Resolution

Hear from Our Global Partners

“The team at T&L is always quick to respond, often within an hour. Knowing they’re there to solve any issue keeps our operations running smoothly—we rely on their support.”

Alexei PetrovRussia

“T&L’s attention to our production needs has been exceptional. Their reliable equipment and quick support help us meet deadlines and keep our processes running seamlessly.”

Fatima Al-SalemSaudi Arabia

“Partnering with T&L has genuinely elevated our business. The quick delivery and dependable support allow us to stay competitive here in the Middle East, where our clients value both quality and consistency.”

John CarterUnited Arab Emirates

“We needed a custom solution for high-precision bending, and T&L delivered. The machines are robust and perfectly tailored to our specs, saving us both time and cost in production.”

Lucas FischerGermany

Previous

Next