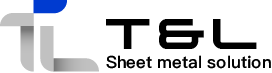

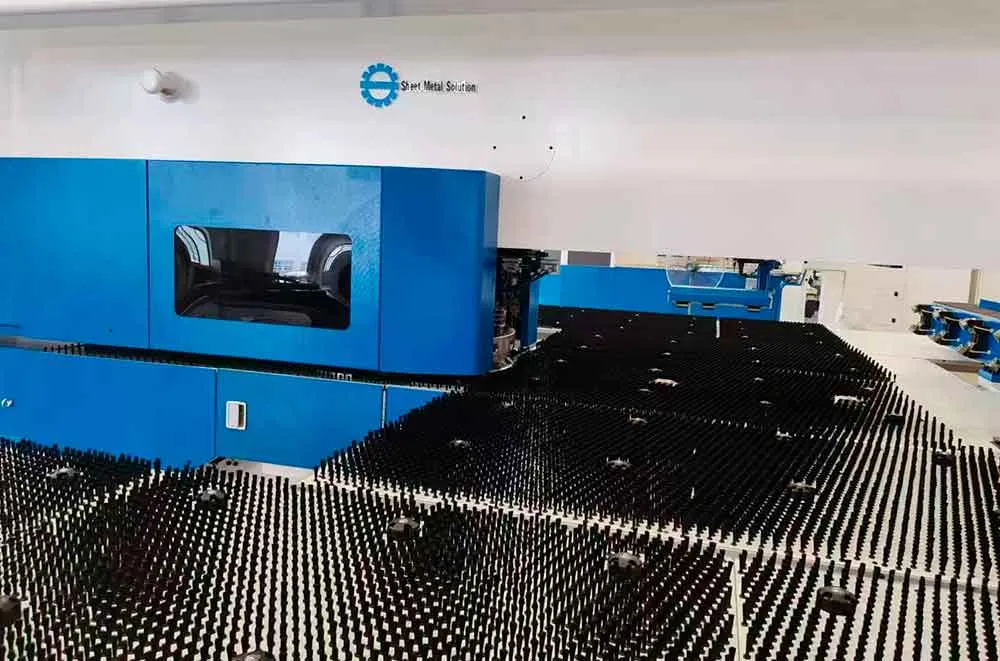

MTE-300 CNC Turret Punching Machine

Model: MTE-300

Brand Name: T&L

Highlights:

- Enlarged space between turrets, convenient for special parts production

- 38 Work stations, more tooling choices

- Follow-up worktable to decrease the resistance of sheet moving and reduce the scratches

- High effiency and high stability, multi-function

Applications:

- Electric cabinet

- High Precision Parts

- Elevator

Technical Parameter

| Model | Unit | MTE-300 |

|---|---|---|

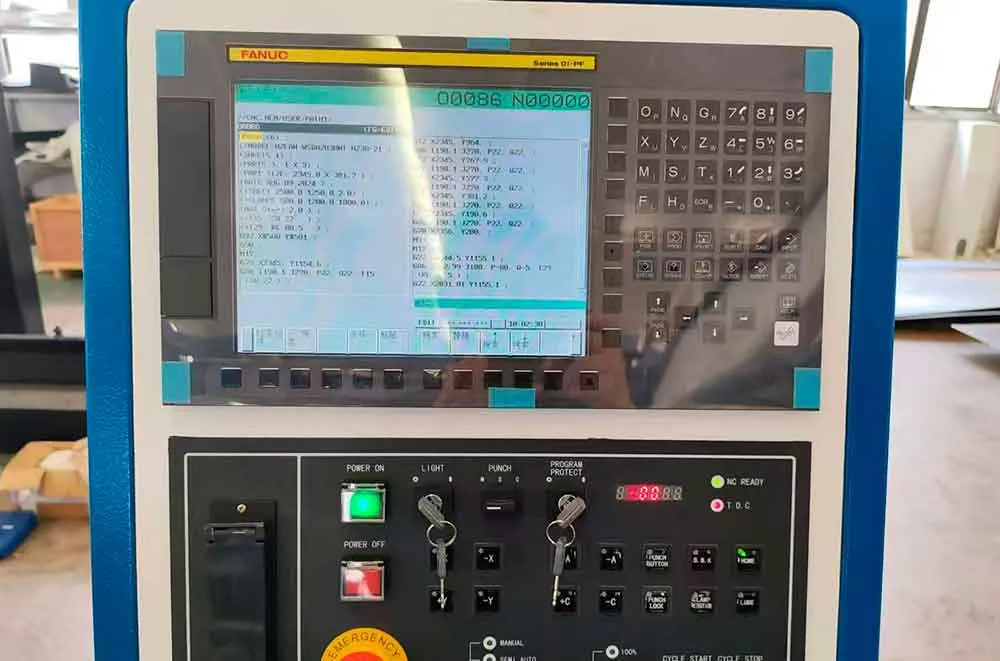

| CNC System | FANUC Oi-PF | |

| Max. Punch Force | ton | 30 |

| X axis stroke | mm | 2500 |

| Y axis stroke | mm | 1500 |

| One time positioning processing plate size | mm | 2500*1500 |

| Max. thickness | mm | 3.2/6.35 |

| Max. Sheet weight | kg | 150 |

| Max.speed of X axis | m/min | 120 |

| Max.speed of Y axis | m/min | 80 |

| Max. Punch Hit at 25mm Pace | hpm | X:360 Y:360 |

| Max. Punch Hit at 5mm Pace with 5mm stroke | hpm | X:580 Y:550 |

| Max. Nibbling Speed | hpm | 1900 |

| Max. Punch Diameter per Time | mm | 88.9 |

| No. of Station | 38 | |

| AI | 2 | |

| Axis | 4+1 | |

| Overall size | mm | 5040*5200*2000 |

| Main motor power | kw | 40 |

| Warranty | Years | 2 |

Specifications apply to standard models. T&L reserves the right to adjust data without notice.

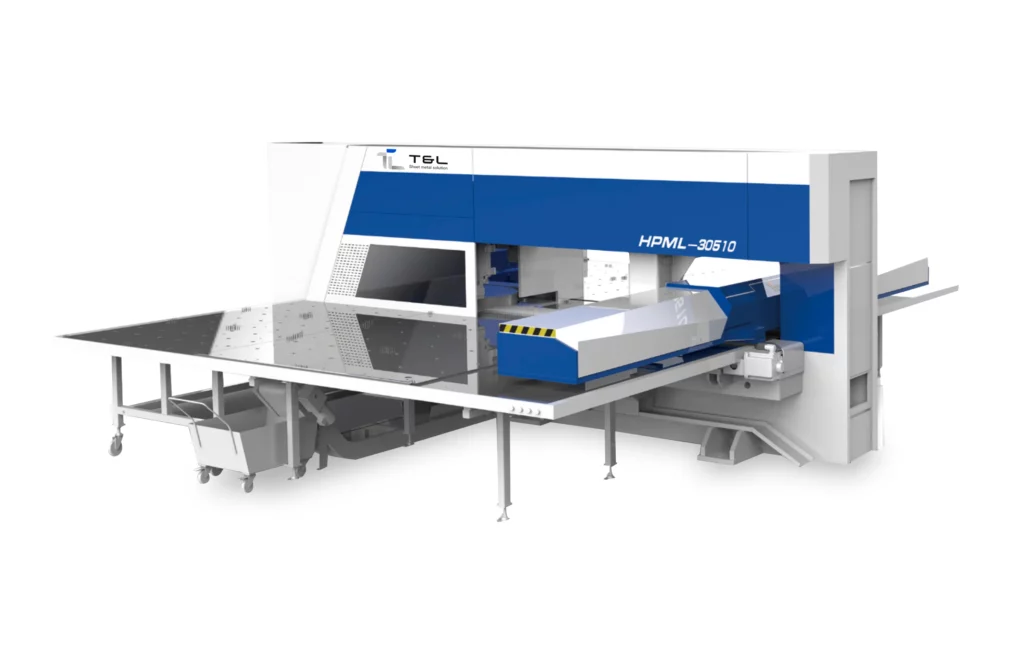

Machine Configuration Overview

Machine Frame

O-shaped closed steel plate is used to weld the

fuselage, and the residual stress is completely

removed after stress relief annealing.

Turret

adopts a special thick turntable with good tool guidance, which ensures the coaxiality of the punch and die, and greatly prolongs the service life of the tool. The double row station makes the die change faster

Machine Worktable

Combination of brush and steel ball support not only reduces the noise and vibration of the machine, but also plays a good role in protecting the surface of the processed plate.

Floating pneumatic clamp

The cylinder adopts force doubling cylinder, which has large clamping force and stable feeding; The integral dovetail carriage has good rigidity and convenient

movement of the clamp.

Machine Configuration Overview

Trust T&L: Leading China Sheet Metal Machine Manufacturer

Reliable Imported Components

Advanced Manufacturing Capabilities

Broad Product Line Coverage

Comprehensive Customization Capabilities

Efficient Multi-step Quality Inspections

High-Value Pricing with Superior Quality

7-30 days Rapid Delivery

1-Hour Response & 12-Hour Resolution

Hear from Our Global Partners

“The team at T&L is always quick to respond, often within an hour. Knowing they’re there to solve any issue keeps our operations running smoothly—we rely on their support.”

Alexei PetrovRussia

“T&L’s attention to our production needs has been exceptional. Their reliable equipment and quick support help us meet deadlines and keep our processes running seamlessly.”

Fatima Al-SalemSaudi Arabia

“Partnering with T&L has genuinely elevated our business. The quick delivery and dependable support allow us to stay competitive here in the Middle East, where our clients value both quality and consistency.”

John CarterUnited Arab Emirates

“We needed a custom solution for high-precision bending, and T&L delivered. The machines are robust and perfectly tailored to our specs, saving us both time and cost in production.”

Lucas FischerGermany

Previous

Next