Panel benders have become an essential machine in the sheet metal fabrication industry, offering high – precision bending solutions for a variety of applications. These machines come in different models, each with its own set of features and capabilities.

Different Models of Panel Bender

Economical Manual Tool Changing Models

Economical manual tool changing panel bender are a great option for small – to – medium – sized enterprises (SMEs) with limited budgets or those with low – volume production requirements. These models typically require the operator to manually change the bending tools when switching between different bending tasks. While this process may be more time – consuming compared to automatic models, it offers a cost – effective entry point into the world of panel bending.

For example, some manual panel bender are designed with a simple and intuitive interface, making them easy to operate even for workers with limited technical skills. They can handle a variety of sheet metal materials, such as mild steel, aluminum, and stainless steel, with a certain thickness range. However, their bending flexibility and overall productivity are relatively lower due to the manual intervention required for tool changes.

High – End Fully Automatic Tool Changing Model

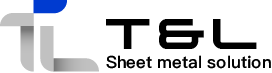

On the other end of the spectrum, high – end fully automatic tool – changing panel bender are the choice for large – scale production facilities and companies that demand high efficiency and precision. These models are equipped with advanced robotic systems and automatic tool – changing mechanisms.

Once programmed, they can quickly and seamlessly switch between different bending tools, allowing for continuous production of complex sheet metal parts. The fully automated operation not only significantly reduces labor costs but also ensures consistent and accurate bending results. For instance, leading brands in the market offer models that can bend sheets with high precision, achieving tight tolerances and complex shapes. They are also capable of handling larger sheet sizes and thicker materials, making them suitable for industries such as aerospace, automotive, and large – scale equipment manufacturing.

The Situation of Low – Priced and Low – End Panel Benders in the Chinese Market

In the Chinese market, there is a prevalence of low – priced and low – end panel benders. One of the main reasons for this is the construction of the machine body. Many of these low – end products use a casting process for the machine body instead of welding which is also used by the first class brand Salvagnini & PrimaPower.

Impact on Machine Stability, Precision, and Service Life

Casting may seem cost – effective in the short term, but it has several drawbacks. Cast – based machine bodies are more likely to experience deformation over time. This deformation can lead to a reduction in the machine’s stability during operation. As a result, the precision of the bending process is compromised. When the machine is unstable, the accuracy of the angles and dimensions of the bending parts will deviate from the desired specifications. Moreover, the overall service life of the machine is reduced. Frequent deformation can cause excessive wear and tear on other components of the panel bender, leading to more frequent breakdowns and the need for costly repairs or early replacement.

Actual Processing Capacity Limitations

In terms of actual processing capacity, these low – end panel benders often fall short. For example, when it comes to bending thick materials, they may not be able to achieve the full – length bends as advertised. The power and structural integrity of these machines are not sufficient to handle the high forces required for bending thick sheets along their entire length. This limitation restricts their application in industries that require the processing of thick – gauge sheet metal, such as heavy machinery manufacturing and some construction – related applications.

The Progress and Potential of Chinese Panel Bender Products

Although Chinese panel bender products currently lag behind world – leading brands like Salvagnini and PrimaPower in terms of technology, the industry is showing remarkable progress.

Continuous Updating and Upgrading

Chinese manufacturers are investing heavily in research and development (R&D) every year. They are constantly updating and upgrading their products to improve performance. For example, new models are being introduced with enhanced control systems that offer better precision and more user – friendly interfaces. Improvements are also being made to the processing ability, such as bending height, extra function. These upgrades aim to close the gap with international competitors and meet the growing demands of domestic and international customers.

Flexible Customization Capability

Another significant advantage of Chinese panel bender products is their flexible customization capability. Chinese manufacturers understand that different customers have unique requirements. Whether it’s customizing the machine’s size, the type of bending tools, or the integration with other production line equipment, they are able to provide tailored solutions. This flexibility allows businesses to optimize their production processes according to their specific needs, whether they are small – scale workshops with niche requirements or large – scale manufacturers looking for specialized solutions.

High Cost – Effectiveness

Despite the technological gap, Chinese panel bender products offer high cost – effectiveness. The combination of continuous product improvement and customization options, along with relatively lower prices compared to international counterparts, makes them an attractive choice for many customers. Businesses that are price – sensitive but still require reliable and functional panel bending solutions can find great value in Chinese – made products. This cost – effectiveness also enables more companies, especially SMEs, to invest in advanced sheet metal processing equipment and improve their production capabilities without incurring excessive costs.

In conclusion, while the panel bender market in China has its challenges in terms of the prevalence of low – end products, the industry is evolving rapidly. With continuous innovation, customization, and cost – effective solutions, Chinese panel bender manufacturers are gradually carving out a larger share in the global market and are expected to make even greater strides in the future.